NOTE: All 3 axis milling operations support rest or leftover machining. This cycle can be used for finishing where excess material has already been cleared and supports single or multiple depths of cut. If a face/surface has even a small gradient, SOLIDWORKS CAM will not generate a toolpath. SOLIDWORKS CAM generates toolpaths only on completely flat areas. The Flat Area cycle uses a pocket out pattern to remove material from feature faces that are flat and parallel to the XY machining plane. The Z Level cycle supports end mill, ball nose, hog nose, taper end mill, taper ball nose and taper hog nose tools.

Cutting starts from the highest location on the model and works down. The cuts follow the contour of the feature at decreasing Z levels based on the Surface Finish you specify. The Z Level cycle is a finish contouring cycle that removes material by making a series of horizontal planar cuts. Z-Level (Waterline Cutting) – 3 Axis Finishing: NOTE: If an interactively defined Contain Area is suppressed or does not exist, the auto contain shape will be used.

The contain area shape can be defined automatically by selecting one of the Automatic Contain Area methods on the Advanced Tab or by interactively defining a Contain Area.

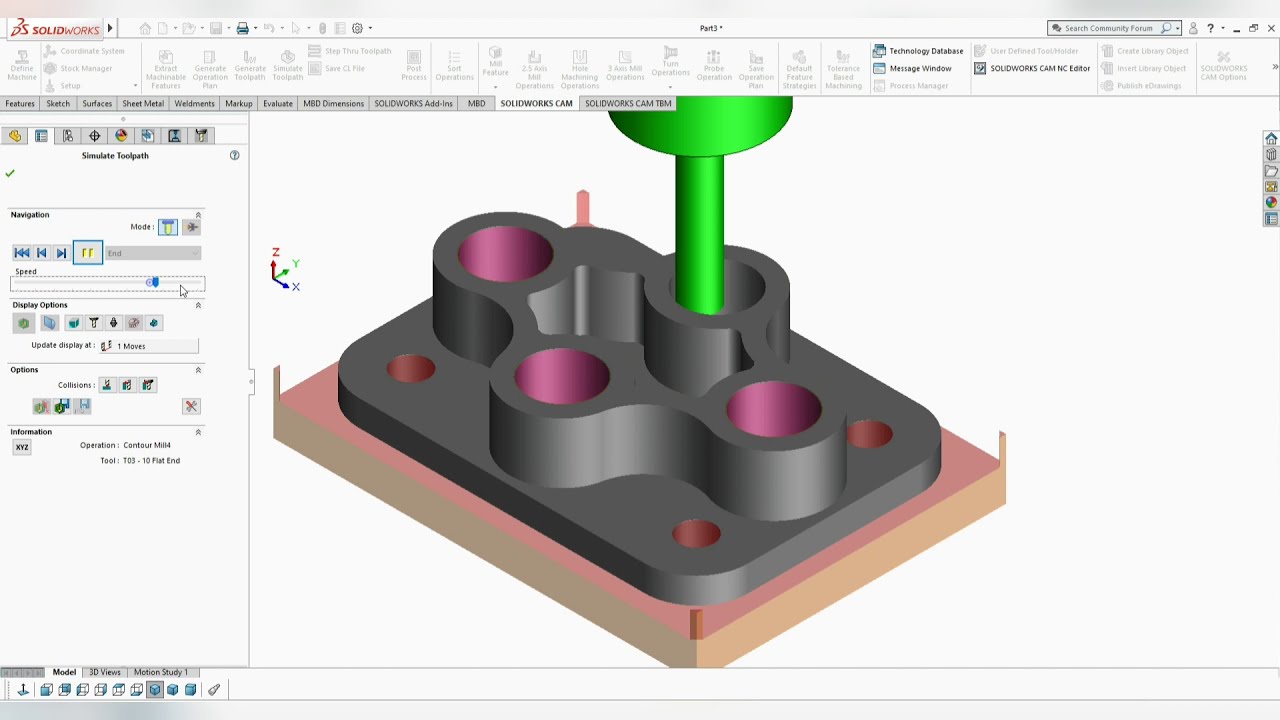

The Area Clearance Operation is used to remove the material between the stock or contain area and the selected feature at decreasing Z depth levels by making a series of parallel cuts across the stock with various patterns.Īlso a Contain Area for Area Clearance Operation removes the material between a contain area shape and the faces defined in the multi-surface feature. SOLIDWORKS CAM Standard includes the following 3 Axis CAM Features:Area Clearance, Z-Level, Flat Area. Working with customers I frequently get asked “What 3 Axis Milling programming capabilities are included with SOLIDWORKS CAM Standard?”

0 kommentar(er)

0 kommentar(er)